Quick Summary:

SKU: JT690158

Price: $19,499.00

Pros:

- Precision and Accuracy

- Variable Speed Control

- X-Axis Powerfeed

- Sturdy Construction

- Versatility

Cons:

- Cost

- Complexity

Personal Perspective: A Machinist's Insight

Having personally used the JET JTM-1050VS2 Milling Machine with 3-Axis ACU-RITE 203 DRO and X-Axis Powerfeed extensively in my workshop, I can attest to its exceptional performance and reliability. As someone deeply immersed in the world of precision machining, I've found this machine to be a game-changer in terms of efficiency and quality.

Precision and Ease of Use

The variable speed control is incredibly intuitive, allowing me to adjust spindle speeds seamlessly depending on the material and cutting tool. This feature alone has saved me valuable time during setup and ensures that I achieve the exact finish I need for each project. Coupled with the ACU-RITE 203 DRO, which provides precise measurement feedback, I can confidently position tools and execute complex milling operations with minimal error.

Moreover, the digital readout is clear and easy to read, even in varying shop lighting conditions. This is crucial for maintaining accuracy throughout long machining sessions. Whether I'm milling intricate patterns or roughing out large pieces, knowing that I can rely on the DRO for precise measurements gives me peace of mind and boosts my productivity.

Efficiency in Operations

One of the standout features for me is the X-Axis Powerfeed. It's a simple addition but makes a world of difference, especially during long machining sessions. Automating the feed process along the X-axis not only reduces operator fatigue but also maintains consistent feed rates, which is critical for achieving uniform cuts across batches of parts. This feature has significantly increased my productivity without compromising on the quality of the finished product.

I particularly appreciate the adjustable speed and direction controls of the Powerfeed. It allows me to fine-tune the feed rate to match the specific requirements of each job, whether I'm working on softer materials that require gentler handling or tougher alloys that demand more aggressive cutting.

Robust Construction and Versatility

The JTM-1050VS2 is built like a tank, with a sturdy Meehanite casting base and column that dampen vibrations effectively. This robust construction not only enhances stability during heavy cutting but also prolongs tool life by minimizing chatter. The machine's dovetail ways on the knee and column further contribute to its rigidity, ensuring precise machining even under challenging conditions.

The versatility of the machine is another big plus. The R-8 spindle taper accommodates a wide range of tooling options, from end mills and drills to reamers and boring bars. This flexibility allows me to tackle diverse milling tasks with confidence, whether I'm working on small, intricate components or large-scale production runs.

Educational Value

In addition to its practical benefits in a professional workshop, I've also seen firsthand how valuable the JTM-1050VS2 is in educational settings. Its user-friendly interface and safety features make it an ideal tool for teaching machining principles to students. The clear digital readout and intuitive controls help beginners grasp fundamental concepts quickly, setting them up for success as they develop their skills in CNC milling and machining.

Seeing students progress from basic operations to more complex milling techniques on the JTM-1050VS2 has been rewarding. Its robust design withstands the learning curve, and the machine's reliability ensures that students can focus on mastering techniques without being hindered by equipment limitations.

Customer Satisfaction

Feedback from other machinists and professionals who have used the JTM-1050VS2 echoes my own experiences. The machine's reliability and consistent performance have earned it a solid reputation in the industry. Whether it's for small-scale prototyping or large-scale production runs, users appreciate the machine's ability to deliver precise results time after time.

Conclusion

In conclusion, the JET JTM-1050VS2 Milling Machine with 3-Axis ACU-RITE 203 DRO and X-Axis Powerfeed is a solid investment for anyone serious about precision machining. Its combination of advanced features, including variable speed control, digital readout, and powerfeed mechanism, sets it apart in terms of performance and efficiency. From enhancing productivity in a busy workshop to facilitating learning in educational environments, this machine proves its worth across various applications. If you're looking to upgrade your machining capabilities or streamline your production processes, consider the JTM-1050VS2 as a reliable partner in your journey towards machining excellence.

Positive Buying Experience with Beaver Industrial Supply

My experience purchasing the JET JTM-1050VS2 Milling Machine from Beaver Industrial Supply was nothing short of excellent. From the initial inquiry to the final delivery, their customer service was outstanding. The team at Beaver Industrial Supply demonstrated deep knowledge of their products and guided me through the selection process with patience and professionalism. They provided comprehensive information about the machine's features and capabilities, ensuring I made an informed decision tailored to my workshop's needs. The transaction was seamless, with prompt updates on shipping and delivery schedules. Overall, Beaver Industrial Supply exceeded my expectations, delivering not only a top-notch milling machine but also exceptional customer service that instilled confidence in my purchase decision.

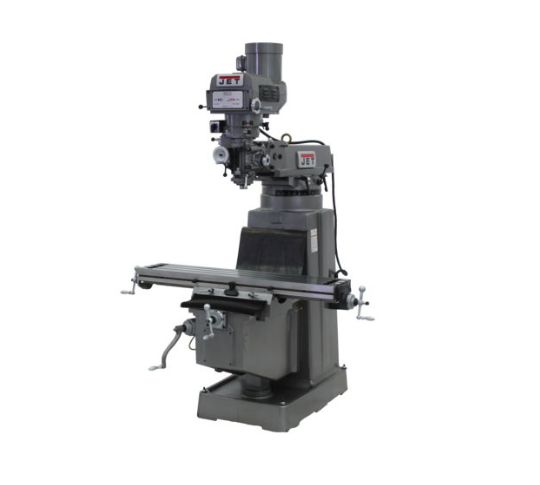

Precision and Power Combined: The JET JTM-1050VS2 Milling Machine

In the world of machining, precision and reliability are paramount. Whether you're a seasoned professional or an aspiring hobbyist, having the right equipment can make all the difference in achieving exceptional results. The JET JTM-1050VS2 Milling Machine with 3-Axis ACU-RITE 203 DRO and X-Axis Powerfeed embodies these qualities, offering a robust solution for various milling tasks. Let's delve deeper into what makes this machine a standout choice in the market today.

Overview of the JET JTM-1050VS2

The JET JTM-1050VS2 is a variable speed vertical milling machine designed to meet the demands of precision machining. It is equipped with a 3-Axis ACU-RITE 203 Digital Readout (DRO), which provides accurate measurement and positioning feedback, essential for intricate milling operations. Additionally, the inclusion of an X-Axis Powerfeed enhances efficiency by automating the feed process, allowing operators to focus on other critical aspects of their work.

Key Features and Specifications

1. Variable Speed Control:

- The JTM-1050VS2 features a variable speed drive system, allowing for precise control over spindle speeds from 60 to 4200 RPM. This capability is crucial when working with different materials and cutting tools, ensuring optimal performance and surface finish.

2. ACU-RITE 203 Digital Readout (DRO):

- The 3-Axis ACU-RITE 203 DRO provides real-time measurement feedback on the machine's X, Y, and Z axes. This digital display enhances accuracy and repeatability, enabling operators to execute complex milling tasks with confidence. The intuitive interface and clear display make it easy to monitor tool positions and make adjustments on the fly, reducing setup time and minimizing errors.

3. X-Axis Powerfeed:

- By integrating an X-Axis Powerfeed, JET has streamlined the milling process. This feature automatically feeds the workpiece along the X-axis, reducing operator fatigue and improving consistency in feed rates, particularly during long machining sessions. The Powerfeed can be adjusted for speed and direction, providing versatility for different types of milling operations.

4. Heavy-Duty Construction:

- The JTM-1050VS2 is built with a solid Meehanite casting base and column, providing exceptional rigidity and vibration damping. This robust construction contributes to stability during heavy cuts, ensuring precise results and extending tool life. The machine's dovetail ways on the knee and column further enhance stability and accuracy, making it suitable for both roughing and finishing operations.

5. Versatile Table and Spindle:

- The machine features a spacious 10" x 50" table, offering ample workspace for various workpieces. The table is equipped with T-slots for securing workholding devices and fixtures, accommodating diverse machining setups. The R-8 spindle taper allows for easy tool changes and supports a wide range of tooling options, making it adaptable to different milling applications and materials.

6. Safety and User-Friendly Design:

- Safety features such as emergency stop buttons, spindle brake, and adjustable depth stop enhance operator safety and control. The machine's ergonomic layout ensures ease of operation and maintenance, with conveniently located controls and clear labeling for quick reference. Built-in coolant systems and chip guards help maintain a clean and safe working environment, promoting productivity without compromising safety.

Applications and Benefits

The versatility of the JET JTM-1050VS2 makes it suitable for diverse machining tasks across industries. Here are some key applications and benefits:

1. Precision Machining:

- Ideal for milling operations that require high precision and dimensional accuracy, such as creating intricate parts for aerospace, automotive, and mold-making industries. The combination of variable speed control and digital readout ensures precise tool positioning and consistent quality in finished parts.

2. Prototyping and Customization:

- Enables rapid prototyping and customization of components, facilitating innovation and adaptation to specific design requirements. Machinists can quickly iterate designs and produce prototypes with confidence, thanks to the machine's reliable performance and ease of operation.

3. Batch Production:

- Supports efficient batch production of parts with consistent quality and performance, enhancing productivity in manufacturing environments. The X-Axis Powerfeed reduces cycle times and operator intervention, allowing for continuous milling operations with minimal downtime.

4. Educational and Training Purposes:

- Suitable for educational institutions and training facilities to teach fundamental and advanced machining techniques, preparing students for careers in manufacturing and engineering. The machine's user-friendly interface and safety features make it an ideal platform for learning CNC milling principles and practices.

Customer Feedback and Reviews

Feedback from users of the JET JTM-1050VS2 has been overwhelmingly positive, highlighting its robust performance, ease of use, and reliability. Machinists appreciate its smooth operation and the accuracy provided by the ACU-RITE 203 DRO, noting that it significantly improves workflow efficiency. Customers have also praised JET's responsive customer support and the machine's durability, making it a long-term investment for their machining needs.

Frequently Asked Questions (FAQs)

1. What are the main advantages of the ACU-RITE 203 DRO on this milling machine?

The ACU-RITE 203 DRO provides real-time measurement feedback on the machine's X, Y, and Z axes. It enhances precision and accuracy by allowing operators to monitor tool positions digitally, making adjustments on the fly. This feature is essential for maintaining consistency in machining operations, reducing setup time, and minimizing errors.

2. How easy is it to change spindle speeds on the JET JTM-1050VS2?

Changing spindle speeds on the JTM-1050VS2 is straightforward due to its variable speed drive system. Operators can adjust speeds from 60 to 4200 RPM easily using the control panel. This flexibility allows for optimal cutting performance across different materials and cutting tools without the need for belt changes.

3. Can the X-Axis Powerfeed be adjusted for different materials and cutting conditions?

Yes, the X-Axis Powerfeed on the JTM-1050VS2 can be adjusted for speed and direction, making it versatile for various machining applications. Operators can fine-tune the feed rate to match the specific requirements of different materials and cutting conditions, enhancing efficiency and ensuring consistent results.

4. Is the JET JTM-1050VS2 suitable for educational purposes and training?

Absolutely. This milling machine is widely used in educational institutions and training facilities to teach CNC milling principles and advanced machining techniques. Its user-friendly interface, safety features, and reliable performance make it an ideal platform for students to learn and practice machining skills in a controlled environment.

5. What maintenance is required for the JET JTM-1050VS2 to ensure optimal performance?

Regular maintenance includes lubrication of moving parts, checking and adjusting belt tension, and keeping the machine clean from chips and debris. It's also important to periodically inspect and calibrate the ACU-RITE 203 DRO to maintain accuracy. Following the manufacturer's guidelines for maintenance will help ensure long-term performance and reliability of the machine.

6. How does the JTM-1050VS2 compare to other milling machines in its class?

The JET JTM-1050VS2 stands out due to its combination of advanced features, including the ACU-RITE 203 DRO and X-Axis Powerfeed, which are typically optional upgrades on other machines. Its robust construction, variable speed control, and versatility make it a preferred choice for machinists and workshops that prioritize precision, efficiency, and reliability in their milling operations.

These FAQs cover some of the common inquiries potential users may have about the JET JTM-1050VS2 Milling Machine, addressing key features, applications, maintenance, and comparisons with other machines in its category.

Related Searches and Variants:

Related Searches:

- JET JTM-1050VS2 Milling Machine review

- JET JTM-1050VS2 with ACU-RITE 203 DRO and X-Axis Powerfeed specifications

- Buy JET JTM-1050VS2 Milling Machine online

- Best price for JET JTM-1050VS2 Milling Machine

- JET JTM-1050VS2 Milling Machine manual

- JET JTM-1050VS2 Milling Machine for sale near me

- JET JTM-1050VS2 Milling Machine parts

- JET JTM-1050VS2 Milling Machine accessories

- Compare JET JTM-1050VS2 vs. [competitor model]

Variants:

- JET JTM-1050VS Milling Machine (without the X-Axis Powerfeed)

- JET JTM-1050EVS Milling Machine (with electronic variable speed)

- JET JTM-1050 Milling Machine (base model without DRO)

- JET JTM-1050R Milling Machine (with R-8 spindle taper)

- JET JTM-1050 Milling Machine with Newall DP500 DRO

0 comments