DETAILS

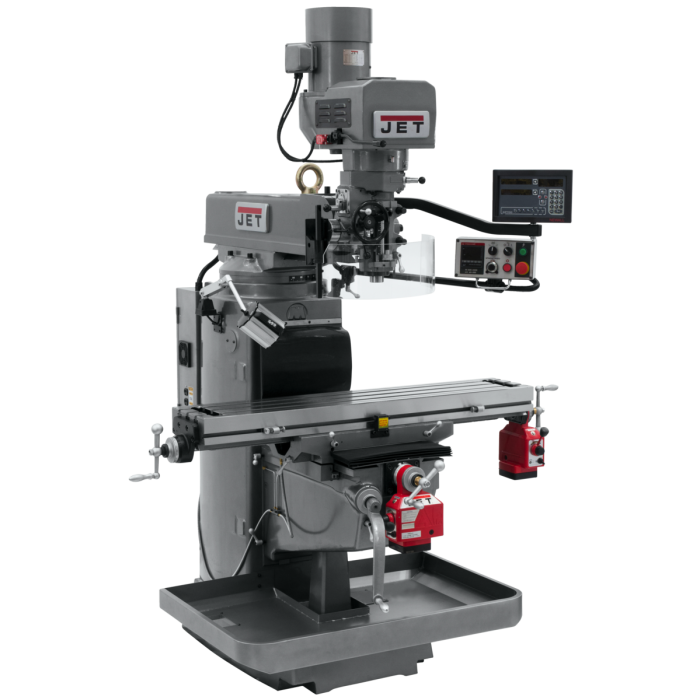

691945, JET JTM-1254RVS 3-X MILPWR CNC W DRW BAR

JET offers complete, factory-installed CNC packages with your choice of 2 or 3-axis CNC controls. The Computer Numerical Control system brings the added precision of digital automation to the process, allowing the user greater control and efficiency. Meehanite® casted JET Vertical Mills with CNC packages deliver accurate results every time. All the features you've come to expect backed by the industry-leading JET Two Year Warranty.

Features:

- CNC Vertical Milling Machine Package JTM-1254RVS

- Features of the ACU-RITE MILLPWR G2 CNC Package

- Certified Meehanite® Castings

- Precision bored and honed milling head

- High precision Class 7 spindle bearings

- Quick Spindle Feed Nut

- Features of the ACU-RITE MILLPWR G2 CONTROLLERFeatures of the ACU-RITE MILLPWR G2 CONTROLLER

- USB + Ethernet compatible

- Simplified navigation that eliminates multiple menu screens

- 12.1″ High resolution display (1024 x 768) with 3D graphics

- 1 GHz Celeron® M processor

- Expanded tool library and Datum offsetsExpanded tool library and Datum offsets

- Program preview provides a graphical representation prior to operation

- Progam size limit increased by 90% to 9,999 steps

- Jog Control allows table movement, quickly from one location to another – using one axis at a time or any two axes simultaneouslyJog Control allows table movement, quickly from one location to another – using one axis at a time or any two axes simultaneously

- 3-D Contouring, ability to import and run G-code files from CAD/CAM programs

- Mirror/Repeat/Rotate/Explode/Merge, easily manipulate, explode and merge part programs to save time and reduce program steps

- Menu-prompted Conversational programming, easily create part programs, edit, reverse, change, delete and copy/move steps – follow the menu prompts and let MILLPWR G2 do the rest

- Built-in Calculator, perform standard, trig and geometry calculations and transfer them directly into part programs

- Custom Pockets and Islands utilize the new optimized path and ramp feed features

- Circles including the Pocket, Frame, Ring and Helix incorporate the new ramp feed feature

- May be used automatically or manually for ultimate shop versatility

- Available offline software

- Estimated runtime feature

- Three Precision ground t-slots

- Turcite B on X & Y Axis

- Adjustable gibs throughout

- CSA/CUS: Following strict guidelines and electrical requirements, these JET Mills are CSA/CUS certified

- Automatic Lubrication every 180 minutes with a flow of 3-6cc reduces maintenanceAutomatic Lubrication every 180 minutes with a flow of 3-6cc reduces maintenance

- Two 115V outlets on electrical box for Powerfeeds onlyTwo 115V outlets on electrical box for Powerfeeds only

Specifications:

- Table Size (L x W) (In.) 12 x 54

- Power Draw Bar Pneumatic

- Spindle Taper (In. x TPI) R-8

- Quill Diameter (In.) 4-1/8

- Range of Spindle Speeds (RPM) 80 – 3,800

- Quill Down Feed Rates (IPR) .0015 – .003 – .006

- Spindle Travel (In.) 5

- Head Movement (Deg.) 90°R & L 45° F & B

- Max Distance Spindle to Table (In.) 23

- Distance Spindle to Column (Max.) (In.) 27-3/4

- Distance Spindle to Column (Min.) (In.) 7-1/2

- Table Longitudinal Travel (In.) 33-7/8

- Table Cross Travel (In.) 15-1/3

- T-Slot Centers (In.) 2-1/2

- Work Table Weight Capacity (Lbs.) 925

- Travel of Knee (In.) 19-1/4

- Travel of Ram (In.) 25

- Column Width (In.) 14-1/4

- Saddle Width (In.) 25-5/8

- Overall Dimensions (L x W x H) (In.) 104-1/4 x 79-7/8 x 92-1/8

- Motor (HP) 5HP, 230/460V, 3Ph

- Weight (Lbs.) 3696

Red Assurance 2-year Warranty:

JET Tools warrants every product it sells. If one of our tools needs service or repair, one of our Authorized Service Centers located throughout the United States can give you quick service. In most cases, any of these Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance and major repair on your JET or Wilton tools.

SPECIFICATIONS

| Jet JTM-1254RVS 3-Axis with MILPWR CNC & Air Power Drawbar 691945 | |

| APPLICATION | Wood Working / Metal Working |

| BRAND COMPATIBILITY | JET |

| Brand | Jet |

| HORSEPOWER | 5.0 HP |

| POWER SOURCE | Electric – Corded |

| PRODUCT TYPE | Tools/Machinery |

| TOOL TYPE | Milling Machines |

| VOLTAGE | 208V-240V 3Ph |

| GTIN | 731325524970 |

.png)